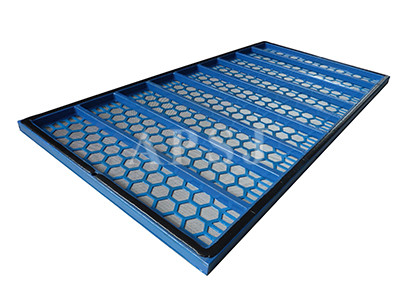

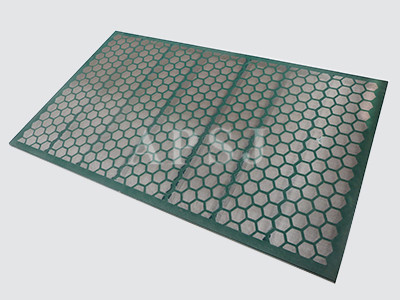

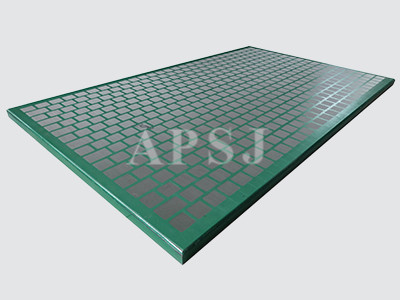

Steel Frame Screens

Steel frame screens are designed with two or three layers of 304 or 316 stainless steel wire cloth, coupled with a steel backing plate and frame for optimal durability and filtration efficiency. The varied mesh and hole sizes contribute to superior filtering performance.

Enhanced strength is achieved through a robust steel frame at the bottom, reinforced by supporting bars and tensioned screen cloth. This combination significantly bolsters screen integrity and longevity, ensuring effective filtration across mesh sizes ranging from 20 to 325.

To mitigate damage, the screen is divided into independent segments, preventing excessive expansion and localized wear. Special rubber plugs facilitate easy repairs, minimizing downtime and replacement costs while maximizing efficiency.

Advantage

- Corrosion-resisting, heat-resisting, wear-resisting.

- Long working life, higher flow rate.

- Easy disassembly, rating of temperature, good performance.

- Conductivity (powder) liquid, trapping (dreg) effect is good.

| Modle | Brand&Model for shaker | Mesh Range | Dimension (Length x Width) |

Weight |

|---|---|---|---|---|

| SJZ-8 | Brandt BL—50 | 40—325 | 1253×635mm | 13.5KGS |

| SJZ-9 | Swaco Mongoose | 40—325 | 1165×585mm | 14KGS |

| SJZ-10 | Kemtron 48 Series | 40—325 | 1220×720mm | 17.5KGS |

| SJZ-11 | Brandt VSM300 | 40—325 | 913×650mm | 12.6KGS |

Applications

- OIL&GAS DRILLING - Solids Control System

- Mud Recycling System

- Mining & Industrial - Slurry Separation Plan